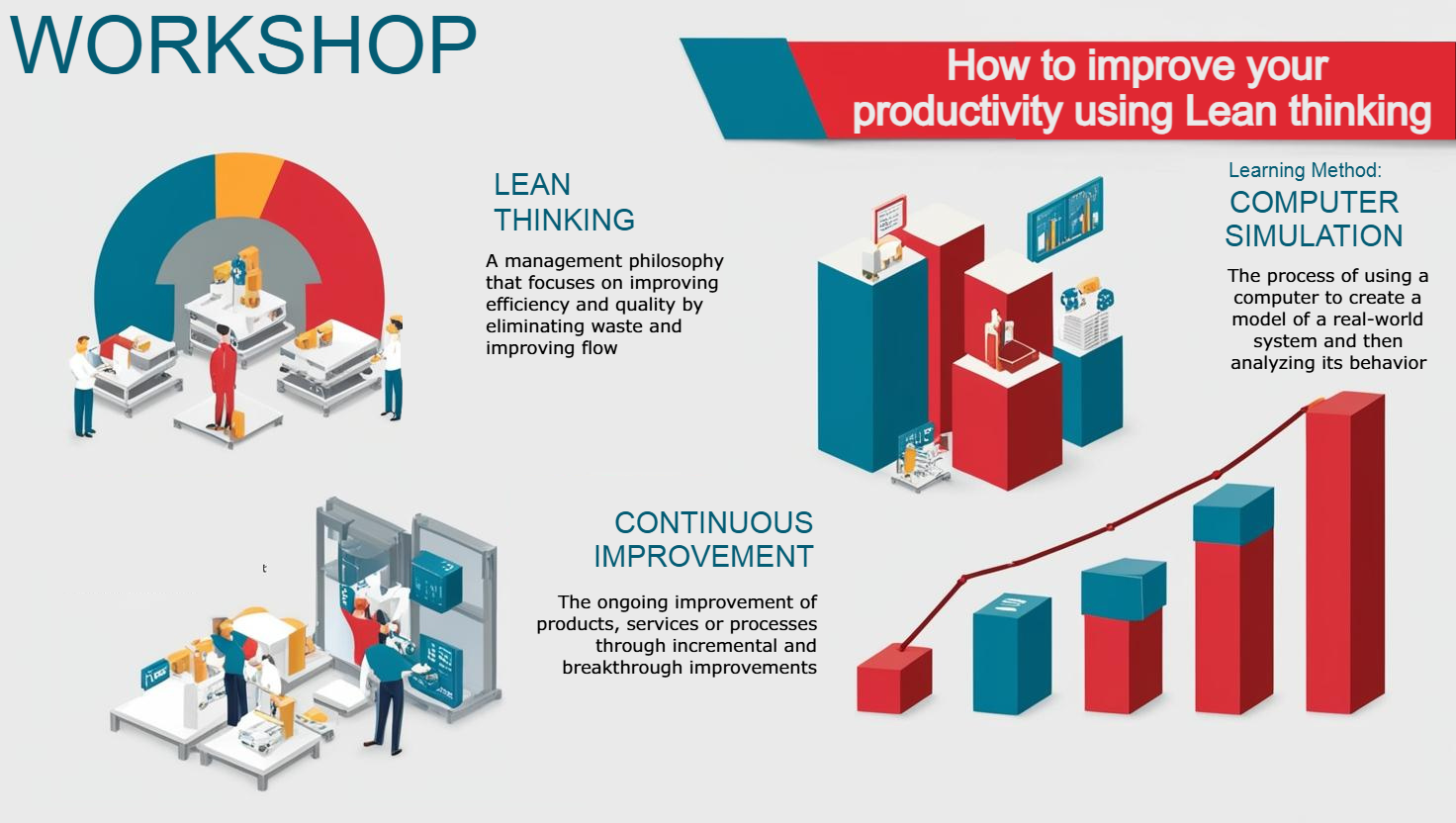

This experiential learning workshop helps participants learn lean thinking through computer simulation. It covers lean principles like value stream mapping, waste identification, and process flow optimization. Participants will engage in simulations, group discussions, and analysis, showing how small changes in process design can increase productivity, reduce waste, and enhance efficiency.

Audience: Professionals interested in operational efficiency, team leaders, managers, or anyone responsible for process improvement.

Objective: Equip participants with the core Lean concepts and demonstrate how to apply them to increase productivity using computer simulation-based learning.

IDR 2.750.000

14/15 Seats Available

Window Alert

Close

Order Summary

| Date | Total |

| 09/05/2025 |

Total

By clicking "Proceed to Payment", I accept the Terms of Use and have read the Privacy Policy

-1630414485.png)